EXCELLENCE IN Equipment DESIGN and development FOR YOUR APPLICATION

For this project an existing Hamco CG800 (1970's era) crystal puller was completely rebuilt into a research platform for melt replenishment Czochalski growth. The original stand and chambers were retained and virtually all other components were replaced. This included new LabView based integrated control system, stand alone temperature control/alarm system, new 60kW power supply, alarm/interlock system for process gas/cooling water and a new seed pulling mechanism. The hot zone components were also redesigned for the new application.

For this project an existing Hamco CG800 (1970's era) crystal puller was completely rebuilt into a research platform for melt replenishment Czochalski growth. The original stand and chambers were retained and virtually all other components were replaced. This included new LabView based integrated control system, stand alone temperature control/alarm system, new 60kW power supply, alarm/interlock system for process gas/cooling water and a new seed pulling mechanism. The hot zone components were also redesigned for the new application.

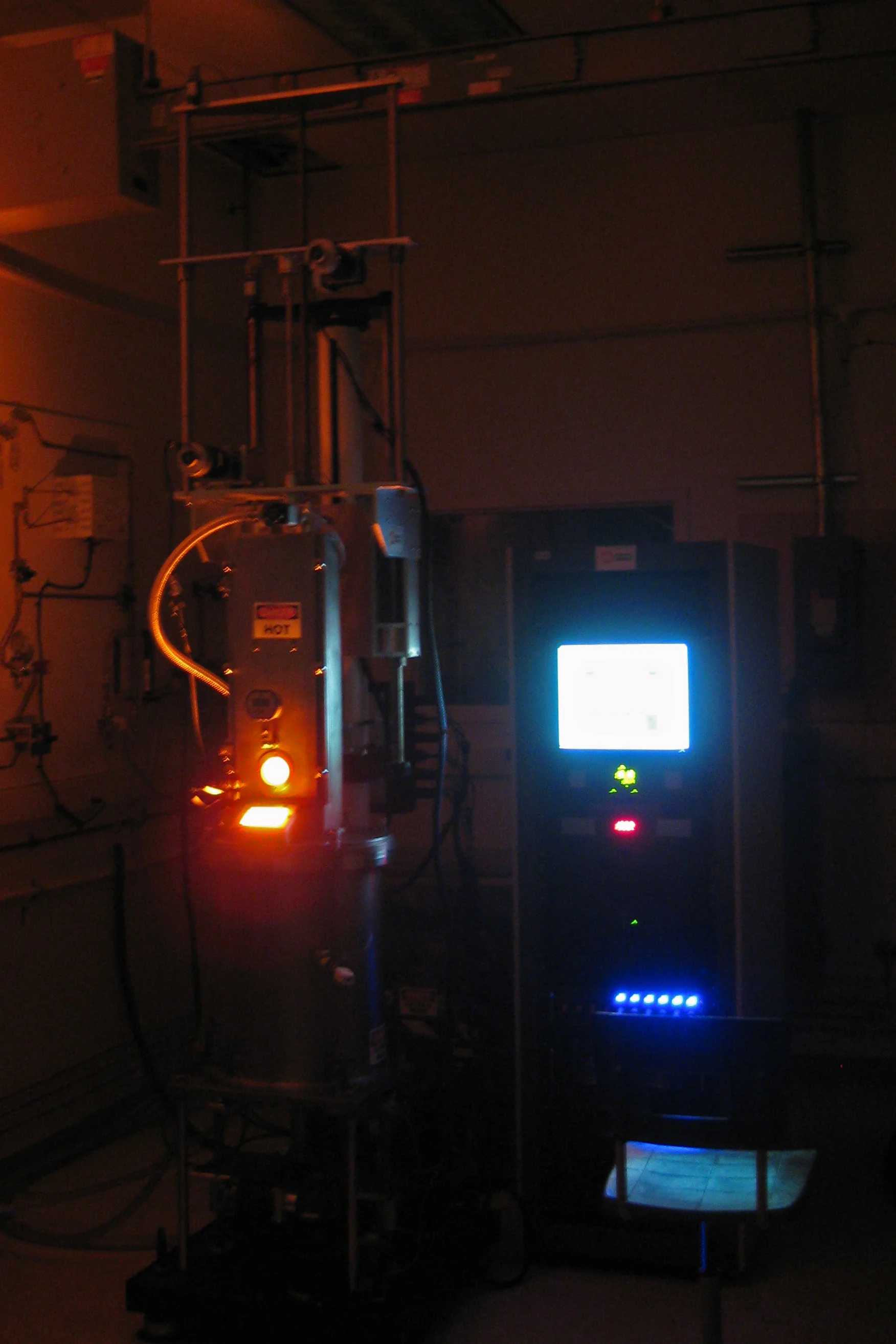

Crystal Pulling System

Puller chambers and control rack are in the foreground. 60kW power supply is visible behind the puller stand. The process gas and cooling water systems are mounted on the wall.

System Control Rack

Integrated system control rack houses heater, motion and process controls/alarms. Systems are integrated into unfied user control though PC running LabView based software.

Heater Control and Temperature Alarm

Panel houses the hardware temperature control and alarm. Extra space was allocated for future auxiliary heaters.

Alarm and Interlock Panel and Motion Control

Cooling Water and Gas Flow are both vital to the safe operation of this equipment. As such, an electomechanical alarm and power interlock panel was developed to ensure safe shut-off in the event of one of these systems failing. A 4-axis servo control system was also installed with the ability to provide extreme low speed motion needed for crucible lift and crystal pulling.

System Testing

Equipment being tested at high temperature.

Seed Dip

Silicon seed being dipped during equipment testing